Water shortage is one of the world’s most pressing problems, and one that is highlighted by the Global Goals number 6 which promises “clean water and sanitation for all”. According to the World Wildlife Fund, more than 1.1 billion people do not have access to water and approximately 2.7 billion experience instances of water scarcity.

There are a number of innovations that are seeking to address this issue. We wrote about a few of them here and interviewed Louise Bleach, head of impact at Desolenator, which has an innovative solar-powered desalination system here.

Now one of the world’s big tech names is targeting the issue. A multidisciplinary team of researchers from GE Research, which is the technology development arm for the General Electric Company (GE), have been selected by DARPA (which co-ordinates scientific research for the US military) to lead a project that could address water scarcity around the world. The team is calling the project AIR2WATER, or Additively Manufactured, Integrated Reservoir To Extract Water using Adsorbents and Thermally-Enhanced Recovery.

In other words the team is working to develop and design a highly compact, portable device that literally can produce clean, safe water out of thin air.

This device, which is small enough to be lifted by just four people, will utilise transformational new material innovations, thermal processes and additive manufacturing (3D printed designs).

The key goal of DARPA’s AWE program is to support the development of small, distributed systems to reduce risks and costs associated with delivering potable water to troops in the field and for humanitarian missions.

Transporting clean, safe water today can involve air and ground vehicle transport over long distances and complex terrain. The prototype device that GE researchers are developing would drastically reduce or potentially eliminate the need for the distribution of water by providing a ready source of clean water directly where troops or participants of humanitarian missions are stationed.

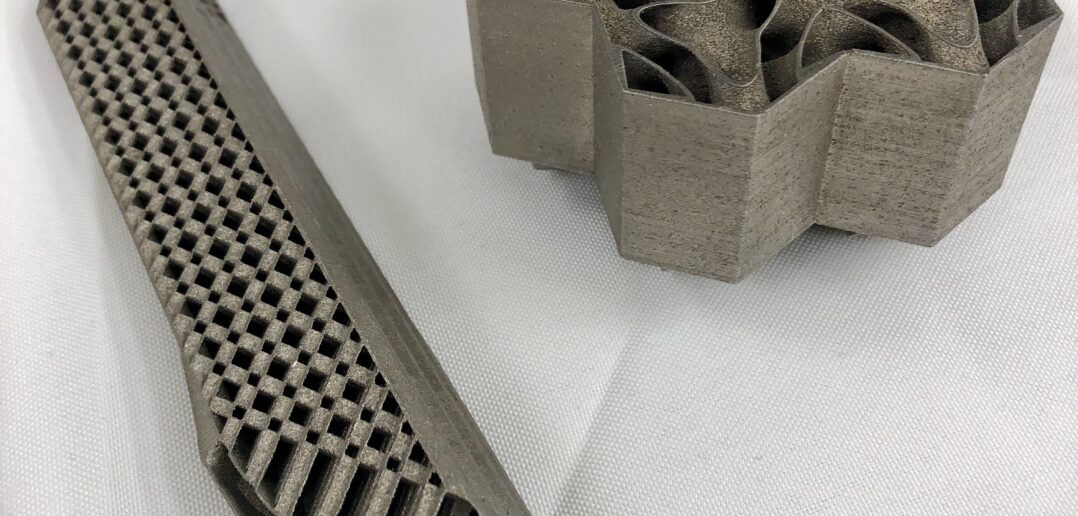

The key technologies being used to produce potable water are sorbent materials to absorb the air and a unique 3D-enabled design of an additively-manufactured heat exchanger that effectively draws in heat over the sorbent materials to release the water.

The GE Research team will be collaborating with top chemists and chemical engineers from UC Berkeley and University of South Alabama, and leading AI experts at the University of Chicago. The team from UC Berkeley, led by renowned Professor of Chemistry, Omar Yaghi, will lead the development of sorbent materials. To help predict and inform the selection of the right materials for the device, the University of South Alabama, led by Prof. Grant Glover, will model the mass transfer and measure the adsorption kinetics, and AI experts from the University of Chicago, spearheaded by Prof. Laura Gagliardi, will utilize AI-guided molecular screening tools.

GE researchers will support these material, modeling and AI developments and lead the overall system integration, including the 3D design of and sorbent integration into the additively-manufactured heat exchanger.

Photo by Julia Volk from Pexels